Direct-to-film (DTF) transfers are transforming decorative design on caps, offering exceptional detail, vibrant colors, and diverse material options. This innovative process involves digitally printing artwork onto thin, flexible films tailored to cap shapes and sizes, providing a versatile, efficient, and cost-effective solution for unique, eye-catching caps. DTF transfers ensure precise reproduction of intricate graphics and fine text, enhance placement freedom, and offer unparalleled durability, making them ideal for events, teams, or individuals seeking to make a lasting impression. Choosing the right material balances aesthetics, durability, and compatibility with cap surfaces, while DTF technology's strong adhesion and versatile design capabilities revolutionize cap decoration, enabling creators to bring intricate patterns and photos to life on various hat surfaces.

“Unleash your creativity with specialized Direct-to-Film (DTF) transfers tailored for cap decoration. This innovative process offers a direct approach to applying intricate designs onto caps, allowing for unparalleled customization. In this article, we explore the benefits of custom sizes, ideal materials, and application techniques. From understanding DTF’s advantages to best practices for long-lasting results, discover how these transfers revolutionize cap design. Unlock your brand’s potential with the art of DTF Transfer.”

- Understanding DTF Transfers: A Direct-to-Film Approach

- The Benefits of Customized Sizes for Cap Decorations

- Choosing the Right DTF Transfer Material

- Application Techniques: Adhering to Caps Seamlessly

- Design Possibilities and Creativity Unleashed

- Best Practices for Long-Lasting, High-Quality Results

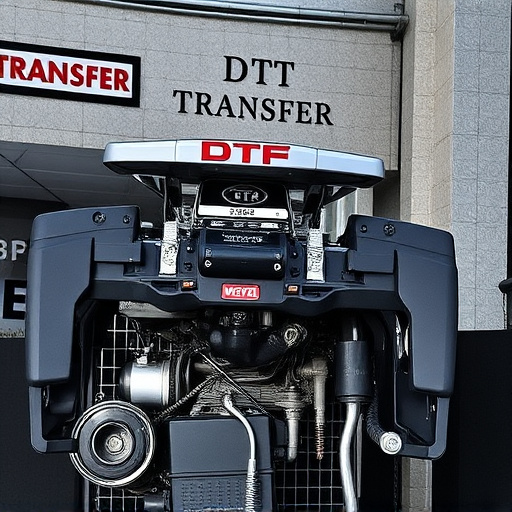

Understanding DTF Transfers: A Direct-to-Film Approach

Direct-to-film (DTF) transfers are a cutting-edge technology revolutionizing the way we create and apply decorative designs, especially on caps. This innovative process involves transferring high-quality images or patterns directly onto a film, which can then be applied to various surfaces, including caps and headwear. Unlike traditional printing methods, DTF offers exceptional detail, vibrant colors, and a range of material options.

The DTF Transfer process starts with designing or sourcing the desired artwork. This art is then digitally printed onto a thin, flexible film, ensuring precision and clarity. The film is precisely cut to match the shape and size required for cap decoration, allowing for intricate designs and custom shapes. This approach provides a versatile, efficient, and cost-effective solution for businesses and individuals looking to create unique, eye-catching caps, especially in small batches or one-off productions.

The Benefits of Customized Sizes for Cap Decorations

Customized sizes for direct-to-film (DTF) transfers offer a multitude of benefits for cap decorations. One of the key advantages is the ability to create unique and personalized designs that perfectly fit specific cap styles and shapes. Unlike standard, one-size-fits-all options, tailored DTF transfers ensure that every detail of the design is accurately reproduced, from intricate graphics to fine text.

Additionally, custom sizes allow for greater flexibility in terms of placement and arrangement on the cap. This precision enhances the overall aesthetic appeal, making each capped creation a standout piece. By accommodating various cap dimensions and allowing for precise positioning, customized DTF transfers contribute to a more polished and professional look, ideal for events, teams, or individuals seeking to make a lasting impression.

Choosing the Right DTF Transfer Material

When selecting a DTF transfer material for cap decoration, consider the type of design and finish you desire. Different materials offer varying levels of durability, gloss, and color accuracy, each catering to specific aesthetic needs. For instance, high-quality vinyl transfers are versatile and suitable for complex graphics with sharp details. They provide excellent longevity and resistance to fading, making them ideal for long-lasting cap art. Alternatively, heat-transfer films specialize in vibrant colors and can handle the rigors of direct application on caps, ensuring a crisp finish.

The choice also depends on the cap’s material and color. Lighter-colored caps might require specific transfer types to ensure the design stands out, while darker caps may demand materials that can penetrate and adhere effectively. Understanding these factors ensures you pick the perfect DTF transfer for your cap decoration project, balancing aesthetics, longevity, and compatibility.

Application Techniques: Adhering to Caps Seamlessly

Direct-to-film (DTF) transfers are a cutting-edge application technique that seamlessly integrates graphic designs onto caps. This process involves transferring high-quality, detailed images directly onto the cap’s surface using advanced printing technology. The result is a crisp, long-lasting design that becomes an integral part of the cap, not merely a sticker or print on top.

One of the key advantages of DTF transfers for cap decoration is their ability to adhere perfectly to the cap’s curvature without bubbles or wrinkles. This seamless integration ensures that the design maintains its visual appeal and durability throughout various wear scenarios. The technique employs specialized adhesives and printing inks designed to bond strongly with materials commonly used in cap construction, guaranteeing a long-lasting and vibrant finish.

Design Possibilities and Creativity Unleashed

Direct-to-film (DTF) transfers open up a world of design possibilities for cap decorations. This innovative process allows for complex and intricate patterns, full-color prints, and even photo-realistic images to be seamlessly integrated onto various cap surfaces. By bypassing traditional printing methods, DTF transfers offer a level of detail and versatility that was once unimaginable. Designers can unleash their creativity, crafting unique and personalized caps that stand out in any collection.

The flexibility of DTF technology empowers creators to translate their artistic visions directly onto hats. From minimalist line art to vibrant gradients, the possibilities are endless. This method also accommodates various cap shapes and styles, ensuring that every design can be tailored to fit perfectly. Whether for fashion, sports teams, or cultural events, DTF transfers provide a cutting-edge way to elevate cap design and create memorable accessories.

Best Practices for Long-Lasting, High-Quality Results

To achieve long-lasting, high-quality results with Direct-to-Film (DTF) transfers for cap decorations, start by selecting top-grade materials. High-resolution images and smooth, durable films are essential to prevent pixelation and ensure the design’s integrity over time. Next, pre-treatment is crucial; clean the caps thoroughly to remove any oils or contaminants that could compromise adhesion.

During the application process, maintain a controlled environment to avoid dust and moisture. Apply the DTF transfer evenly, using gentle pressure to secure it without causing damage. Curing the film under appropriate conditions, as recommended by the manufacturer, guarantees optimal bonding. Regularly inspect the caps post-application for any air bubbles or misalignments, addressing them promptly to maintain aesthetic appeal and long-term durability.